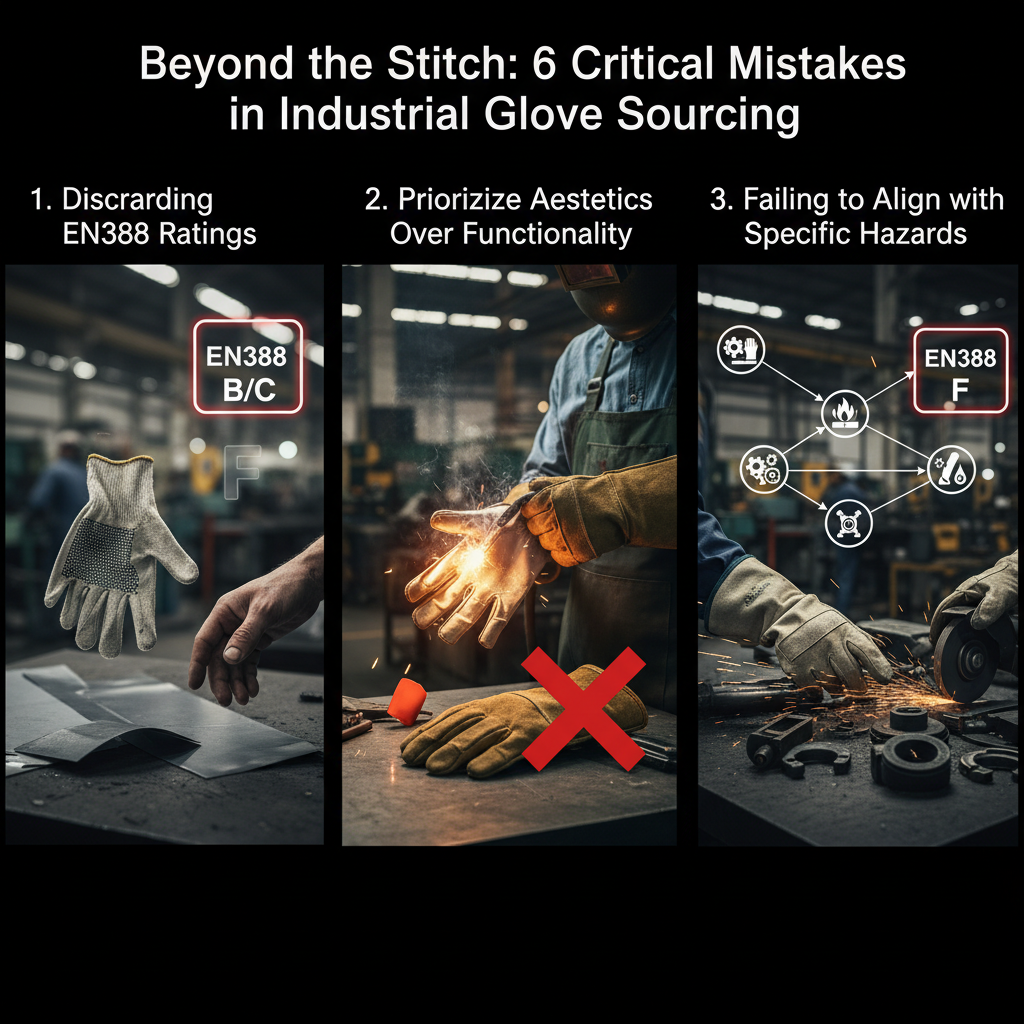

Beyond the Stitch: 6 Critical Mistakes in Industrial Glove Sourcing

Crafting Glove Excellence Since 2002, RX Qo‘lqoplari has witnessed firsthand the challenges businesses face in securing proper hand protection. As a global leader specializing in cut and sew gloves—from everyday essentials to robust industrial workwear—we do more than manufacture; we guide our partners through the complexities of safety compliance.

This guide explores the most common procurement pitfalls and how to avoid them.

1. Disregarding EN388 Ratings

A frequent and dangerous oversight is ignoring the EN388 rating system, the definitive European standard for mechanical protection. This benchmark evaluates a glove’s resistance to abrasion, cuts, tears, punctures, and impact.

Many buyers make decisions based on price points rather than empirical data. For example, if your team handles sheet metal, an anti-cut glove rated EN388 Level F is non-negotiable. Relying on a Level B or C glove offers inadequate defense.

💡 Best Practice

Always demand verified EN388 test reports. At RX Gloves, precision is paramount; we ensure our clients understand exactly what the numbers mean for their specific safety requirements.

2. Prioritizing Aesthetics Over Functionality

It is easy to be drawn to gloves that look sleek or feel lightweight, but prioritizing style over protection is a critical error.

For instance, welders require gloves crafted from heat-resistant leather with reinforced stitching. Swapping these for thinner, more "comfortable" fabric gloves might improve dexterity, but it compromises safety against sparks and molten metal.

RX Gloves Insight: We believe in "Precision in Every Stitch." While we strive to weave functionality with style, we never allow aesthetics to undermine the protective integrity required for industrial workwear.

Balancing aesthetics with rigorous safety standards is key to effective protection.

Balancing aesthetics with rigorous safety standards is key to effective protection.

3. Failing to Align Gloves with Specific Hazards

In safety procurement, a "one-size-fits-all" approach is a fallacy. Every industrial task carries a unique risk profile, and gloves must be matched to these specific threats.

- Metalworking: Requires high-performance anti-cut gloves.

- Automotive Assembly: Needs oil-resistant gloves with superior grip.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. RX Qo‘lqoplari cURL Too many subrequests. cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

✅ Best Practice

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

The best gloves in the world cannot protect a worker who doesn't know how to use them. Training gaps—such as using the wrong glove for a task—are common causes of injury.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.